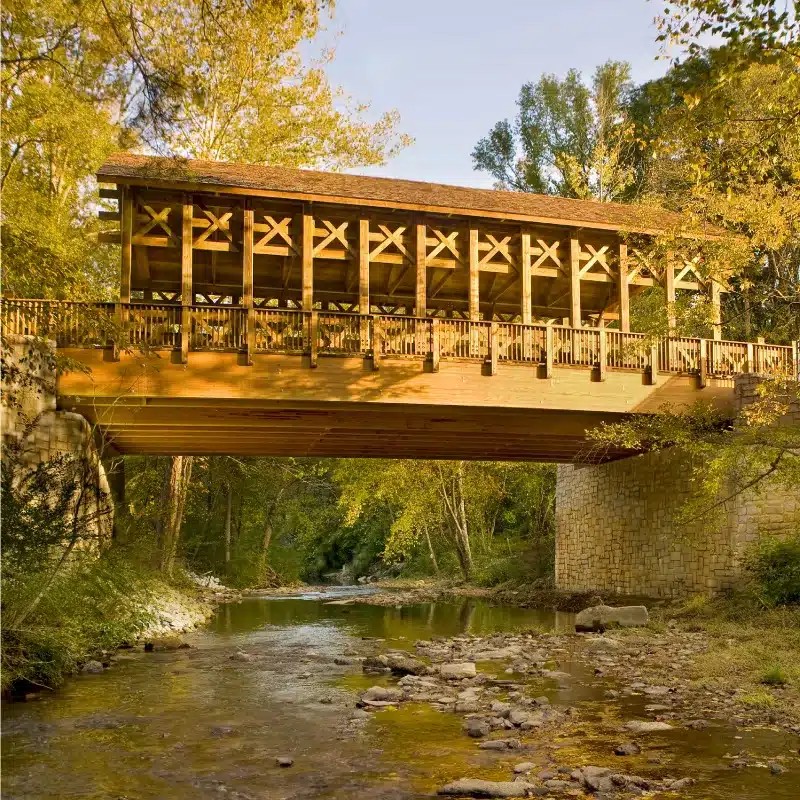

Create Timeless Connections

Timber bridges are more than just a physical link from one side to another. It's a pathway to memories, emotions, imagination, and a profound connection to nature. Discover York Bridge Concepts bespoke premium timber crossings designed to offer you not only a way to reach your destination but also a gateway to an entirely new experience.

Join a Legacy of Over 8,000 Timber Bridges

Leverage Four Decades of Expertise

Choosing to collaborate with York Bridge Concepts, taps into nearly 40 years of unparalleled expertise in the timber bridge industry. Our experienced professionals are here to assist you in making informed decisions about your timber crossing solution.

No matter the scale or complexity of your crossing needs, we have the experience to design and build a solution that is not only eco-friendly but also incredibly durable and aesthetically pleasing.

Popular Bridge Types

Immerse yourself in the artistry of York Bridge Concepts' timber bridge construction, where every project tells a story of innovation, sustainability, and beauty. These timber bridge projects unveil the ballet of construction, featuring cutting-edge techniques that harmonize with the organic grace of timber. Each timber bridge type captures the essence of our commitment to quality, durability, and aesthetic appeal, showcasing the transformation of raw materials into stunning timber bridges. York Bridge Concepts invites you to experience the magic of our construction processes, demonstrating that beyond engineering, there is an art to building bridges that stand the test of time.

dive deeper into York Bridge Concepts' timber Bridge Mastery

Embark on a journey across the waters with York Bridge Concepts. Our top-down construction methodology allows us to create stunning bridges that not only span bodies of water but also become iconic landmarks. From concept to completion, we engineer structures that stand as a testament to both human ingenuity and environmental responsibility.