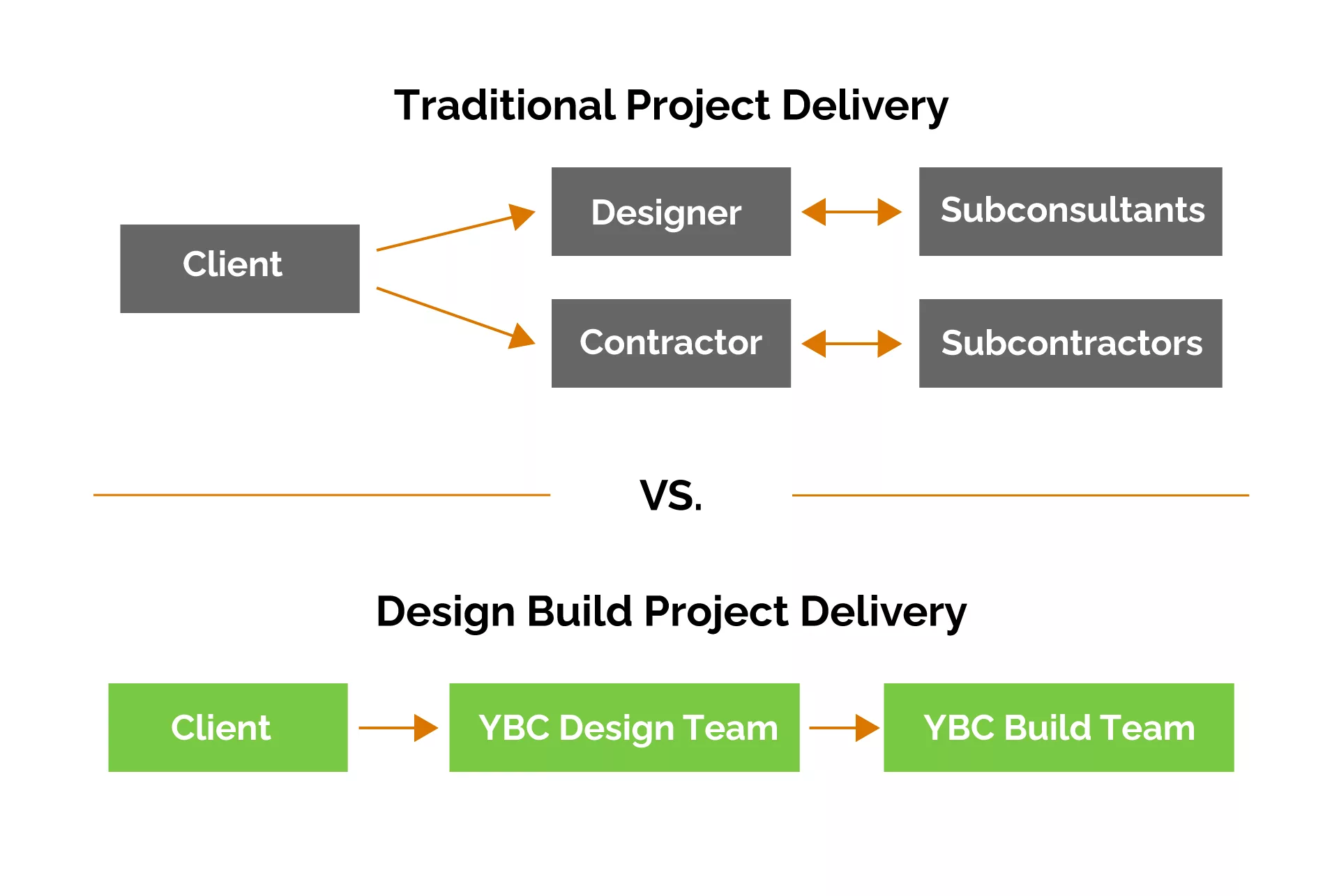

What is design build?

Explore YBC's process of creating iconic timber bridges

Collaboration & efficiency

How Does our design build process work?

YBC is dedicated to bringing your vision to life through collaborative solutions. With nearly 40 years of experience, we understand the challenges you may face when it comes to crossing projects. Just know that YBC is here to help you overcome them with practical and innovative solutions.

Our Design Build process lies at the heart of our approach. We prioritize the surrounding environment, your unique vision to create a crossing that is unique. From the initial concept to the final execution, we are with you every step of the way.

The Design Phase

step 1

Understanding Your Vision

The journey begins with you. The foundation of YBC's success is actively listening to what your vision, goals, and requirements are for your project. By meeting with our Bridge Consultants, we will both gain a comprehensive understanding of your project at hand.

step 2

site assessment

This is one of the most crucial steps in the process. Understanding your site-specific scope by studying the topography, environment, hydrology, and soil condition factors allows YBC to utilize our expertise to create a bespoke package for your crossing.

step 3

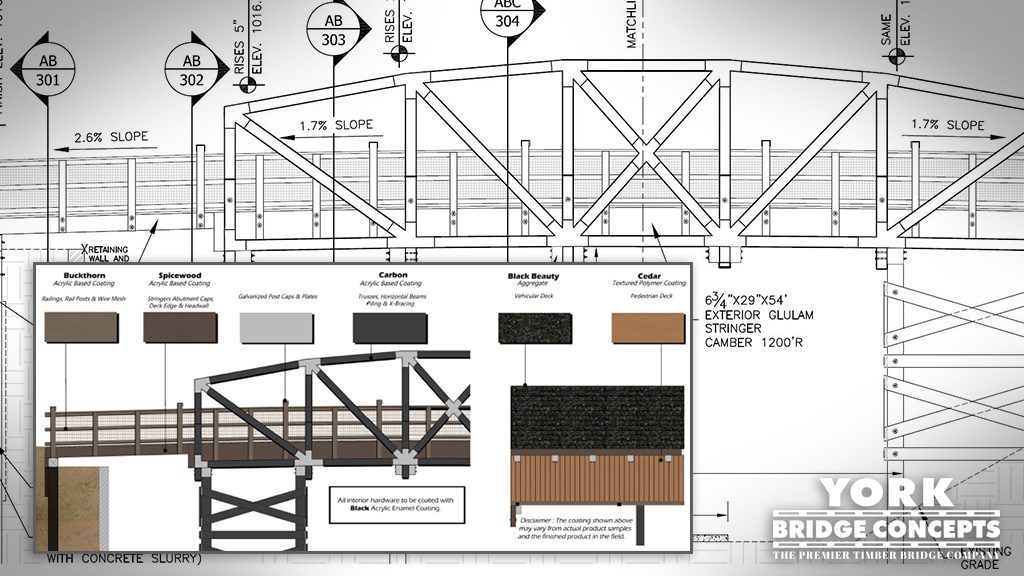

design

This step is the core of YBC's business. Our team of talented designers will collaborate with you to bring your vision to life. We utilize cutting-edge techniques and materials to create the crossing you will enjoy for generations.

step 4

Material Selection

Our procurement team will work to find the best long-lasting materials and finishes to create an awe-inspiring crossing that suits your needs and vision. We carefully select high-quality materials from responsibly managed forests. This process ensures the structural integrity and aesthetics that complement the surrounding environment

82%

CLIENTS PREFER

DESIGN BUILD

Construction organizations plan to use contractors that use the design-build process over the next five years.*

67%

INCREASE OF UTILIZATION IN THE INDUSTRY

Organizations that plan on utilizing companies that use the design-build methodologies in their processes.*

38%

reduction of construction time

Organizations see significantly faster build times versus traditional construction projects.**

The Build Phase

step 5

Permitting Collaboration

We support our clients with engineering packages to gain the approval of the governing jurisdiction. With YBC's national presence, we have experience permitting in every state. Note: YBC does not handle permitting.

step 6

master craftsmanship

This is where YBC shines. Our crews have a combined experience of over 100 years. Most YBC foremen have extensive experience in timber bridge building. Our experience is what sets us apart from the competition. We use advanced techniques that guarantee efficiency, quality, environmental guidelines, and adherence to project timelines.

step 7

On-site construction

Our teams diligently adhere to our uncompromising attention to quality. YBC's QC process meets or exceeds the highest safety and industry standards. We mobilize our custom, heavy-duty equipment to your location. This process mitigates as much risk as possible to your project by being able to make adjustments as needed.

step 8

Inspection & Maintenance

Key Features of the thousand trails bridge

*A Guide To Design Build: https://constructionblog.autodesk.com/design-build-construction/

**KConn Construction: https://www.kconinc.com/design-build-vs-traditional-construction-whats-the-difference/

Create Your Legacy Today

Discover the intersection of strength, durability, and environmental responsibility with York Bridge Concepts. Let's build a bridge to the future together.