National Timber Bridge Builder

We offer design-build services for pedestrian & vehicular timber bridges with on-site construction throughout the US.

Timber Bridge Design & Construction

Are you searching for a "bridge builder near me?" For over 30 years, we’ve been one of the premier national timber bridge builders with timber bridge construction in nearly all 50 states as well as internationally. So, remember not to limit yourself to your regional area when looking for a "bridge builder near me". We would love the opportunity to discuss your project.

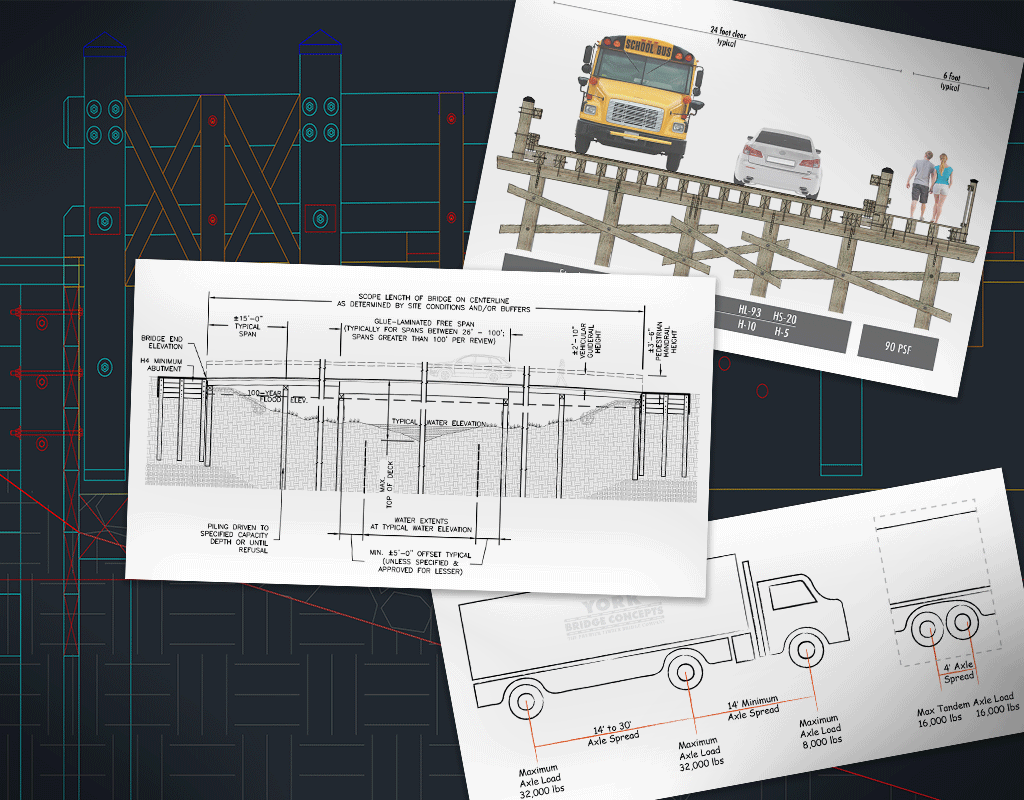

In addition to the feature projects shown, we have spanning profile drawings, section views, and loading diagrams to help you with your planning. Feel free to sign up for or download anything of interest below. Looking for more, visit the York Bridge Design Center.

York Bridge Design Center

Project Galleries

Main Bridge Gallery

Vehicular Bridge Gallery

Pedestrian Bridge Gallery

Capabilities & Design-Build Process

Culvert Or Bridge

If you're considering using a culvert for your crossing project. Click below to understand the best fit for your project.

Spanning Solutions

Spanning a crossing is one of the most important aspects of your crossing project. Find the best solution for your crossing needs.

Uses & Capacities

The load capacity of a timber bridge may surprise you. See specs for different loads and uses that will help your decision-making process.